Products Description

Advantage for cemented carbide wire drawing dies

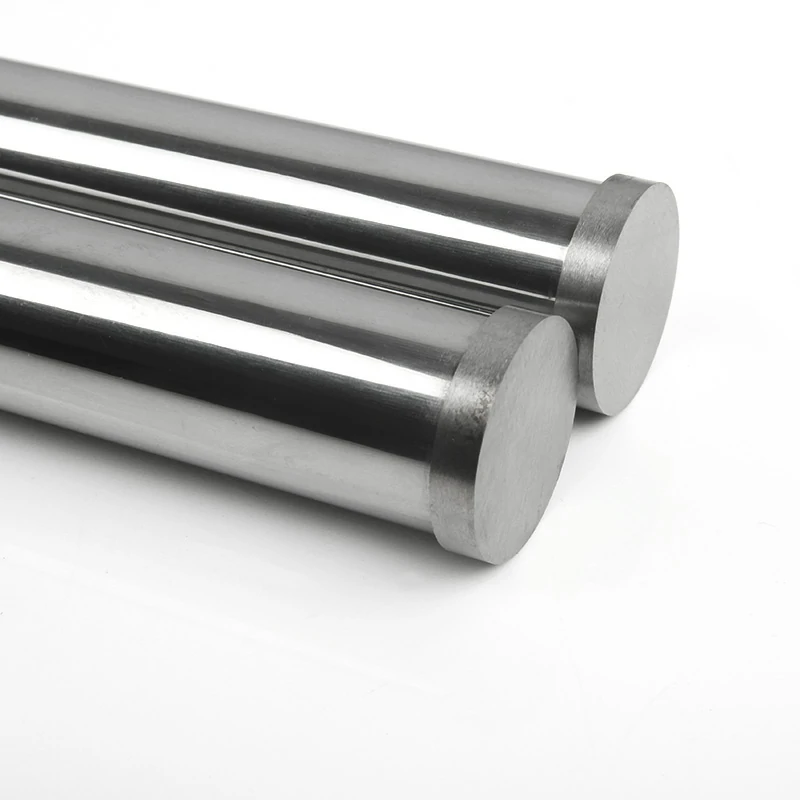

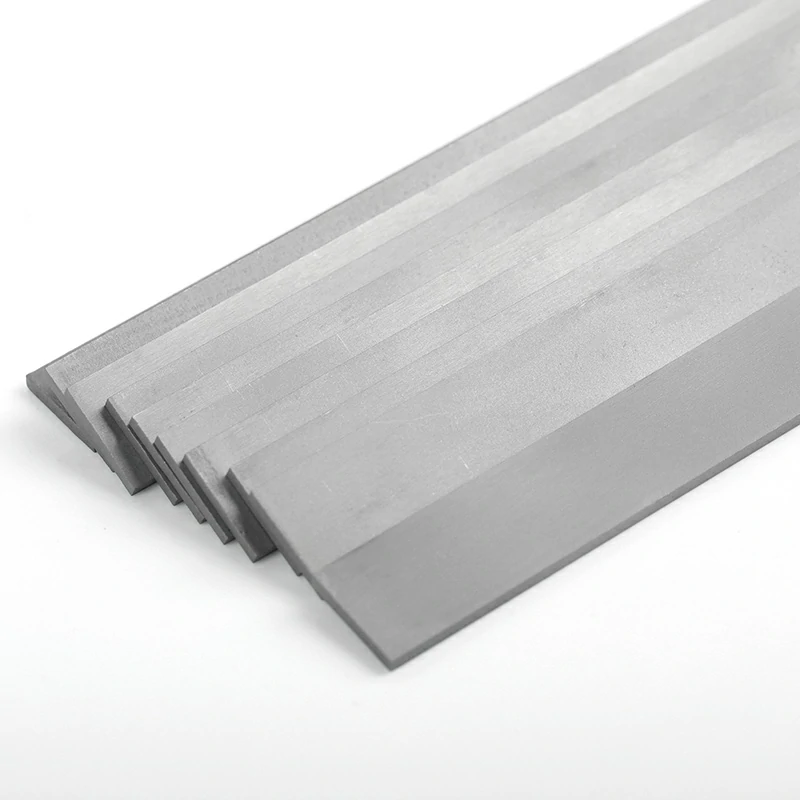

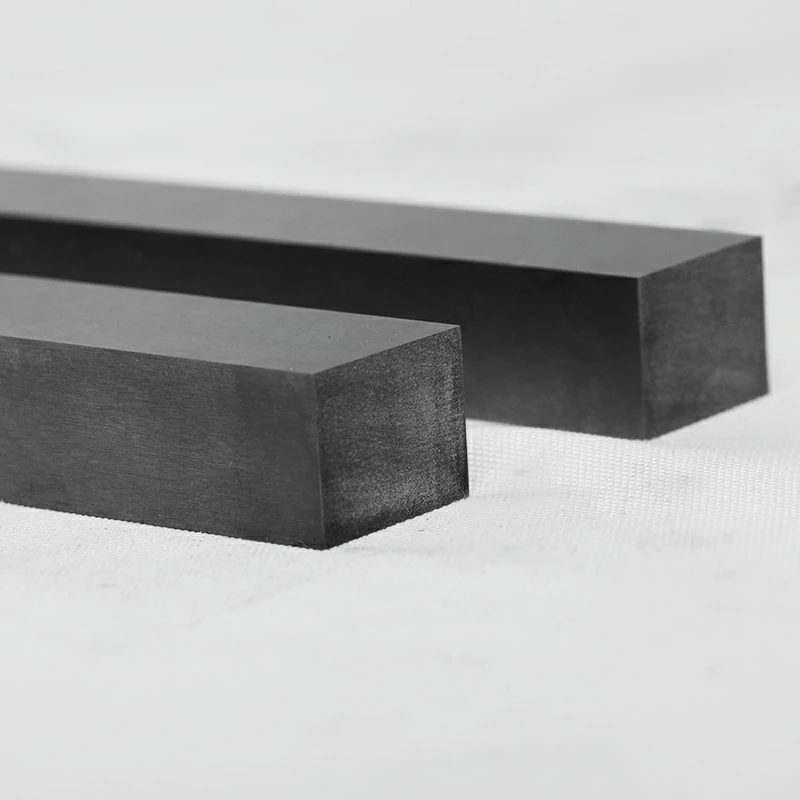

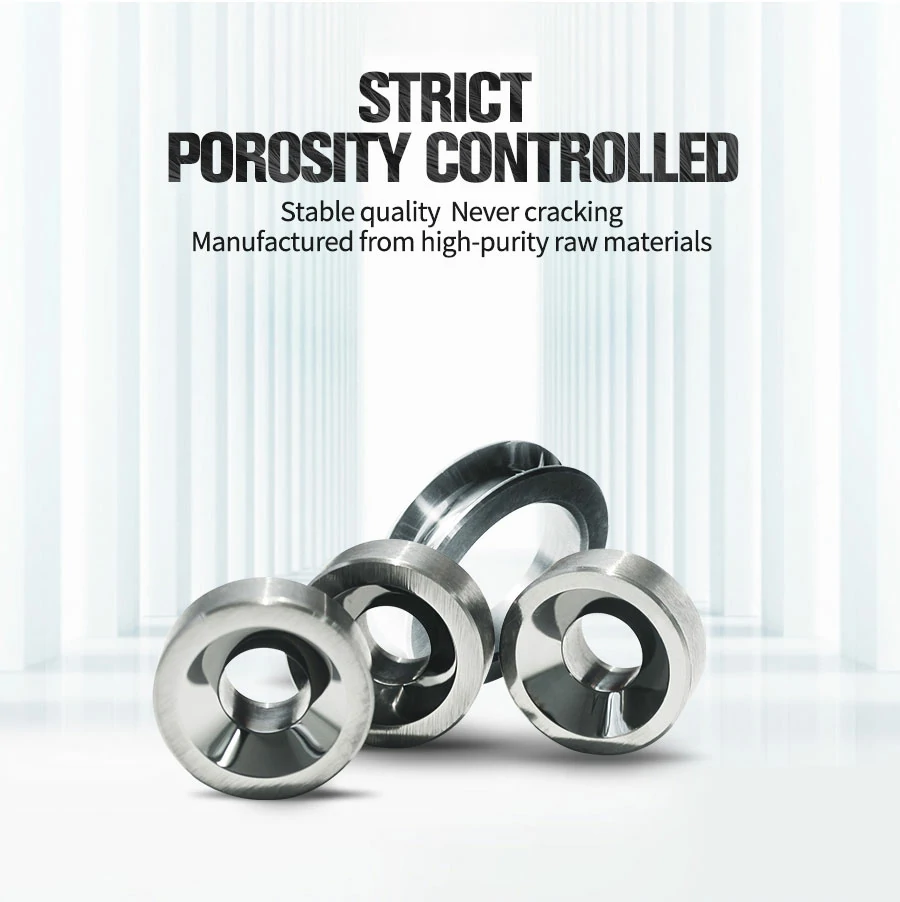

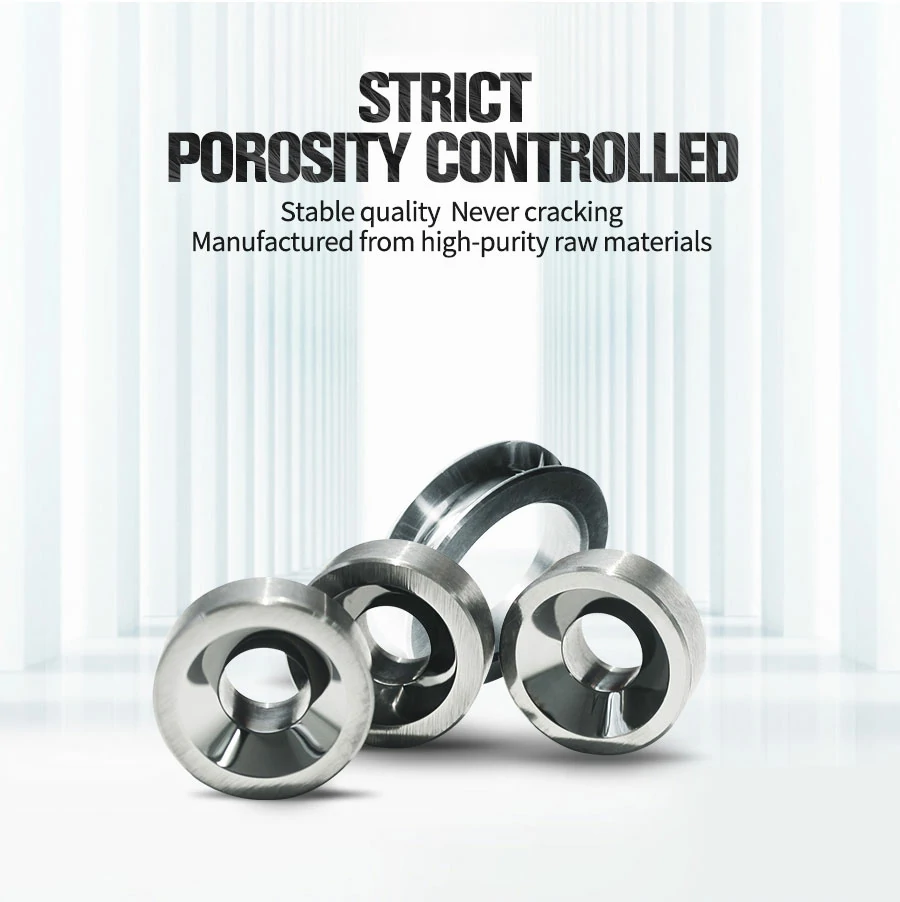

Cemented carbide wire drawing dies are made of high quality cemented carbide for the die core, which has high hardness, good thermal conductivity and low friction coefficient.

Cemented carbide wire drawing die (tungsten steel die or tungsten carbide die) is made of high quality cemented carbide as die core, which has high hardness, good thermal conductivity and low friction coefficient. Tungsten carbide wire drawing dies are easy to make, corrosion resistant, impact resistant and inexpensive. They are suitable for drawing ferrous metals, large size wire and for use in poor drawing conditions.

Grades and applications of Cemented carbide wire drawing dies

Cemented carbide wire drawing dies are widely used for drawing wire. Wire drawing is a manufacturing process used to reduce or change the cross-section of a wire by using a series of drawing plates or dies. Steel wire drawing, inside which a "nib" is inserted inside a steel casting of tungsten carbide.

Grade | Density g/cm³ | Strength MPa | Hardness HRA | Applications |

YG6X | 14.95 | 1800 | 91.5 | Suitable for making drawing dies with bore less than ¢6.00mm. |

YG6X | 14.95 | 1900 | 90.5 | Suitable for making drawing dies for non-ferrous round bars with bore less than ¢20.00mm and tubes with bore less than ¢10.00mm. |

YG8 | 14.8 | 2200 | 89.5 | Drawing dies for the production of round bars and tubes of steel and non-ferrous metals. |

YG10 | 14.5 | 2400 | 88.5 | For drawing steel bars and tubes with high shrinkage. |

YG15 | 14 | 2800 | 87 |

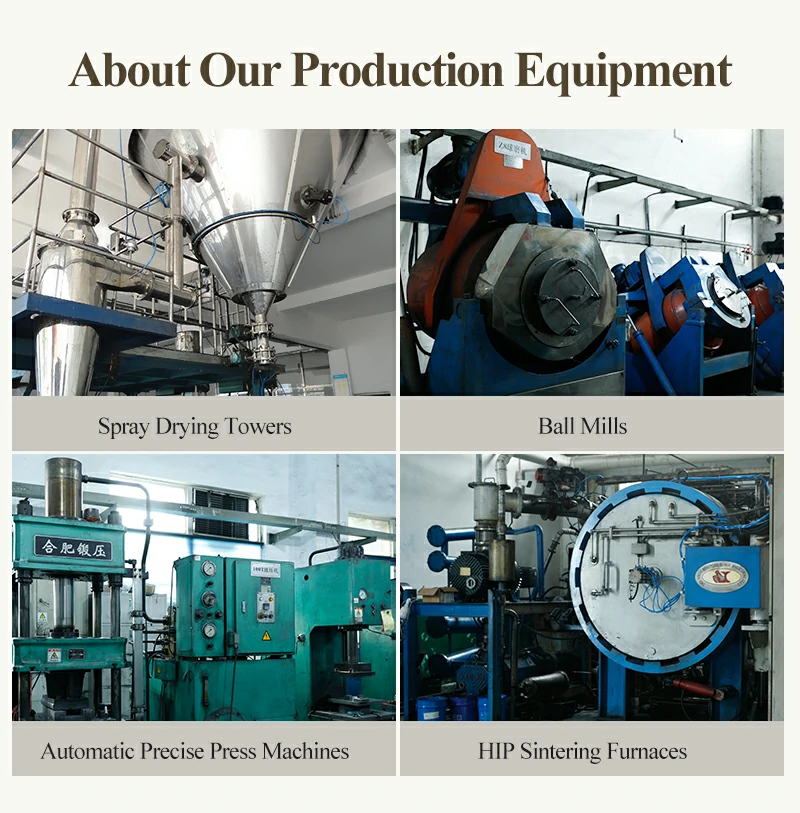

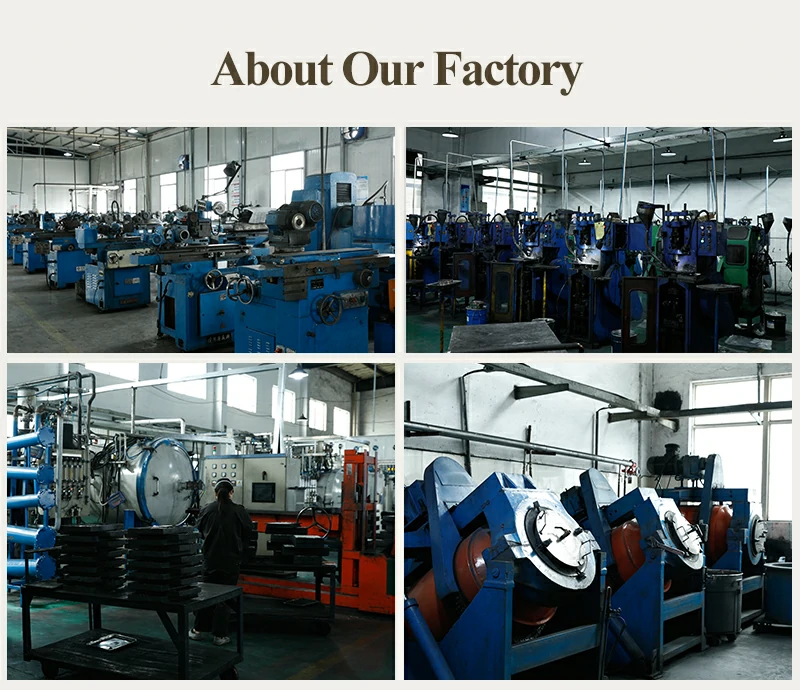

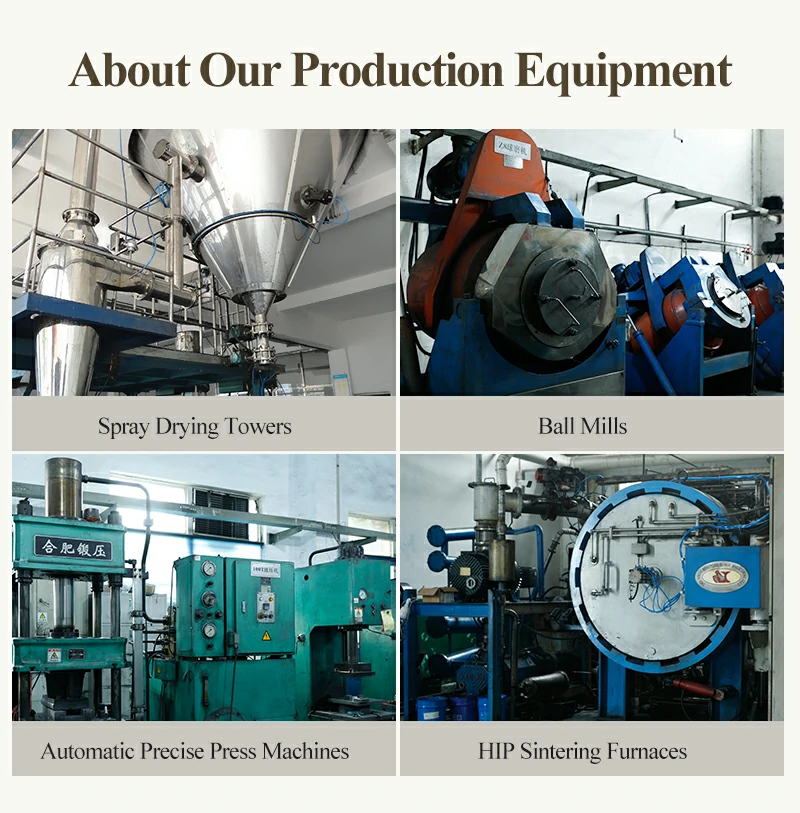

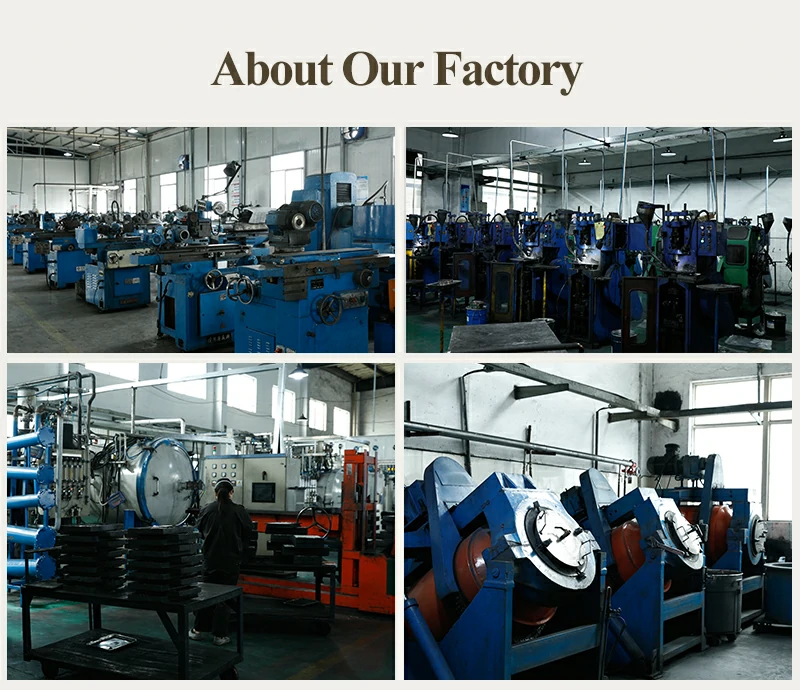

Company Profile