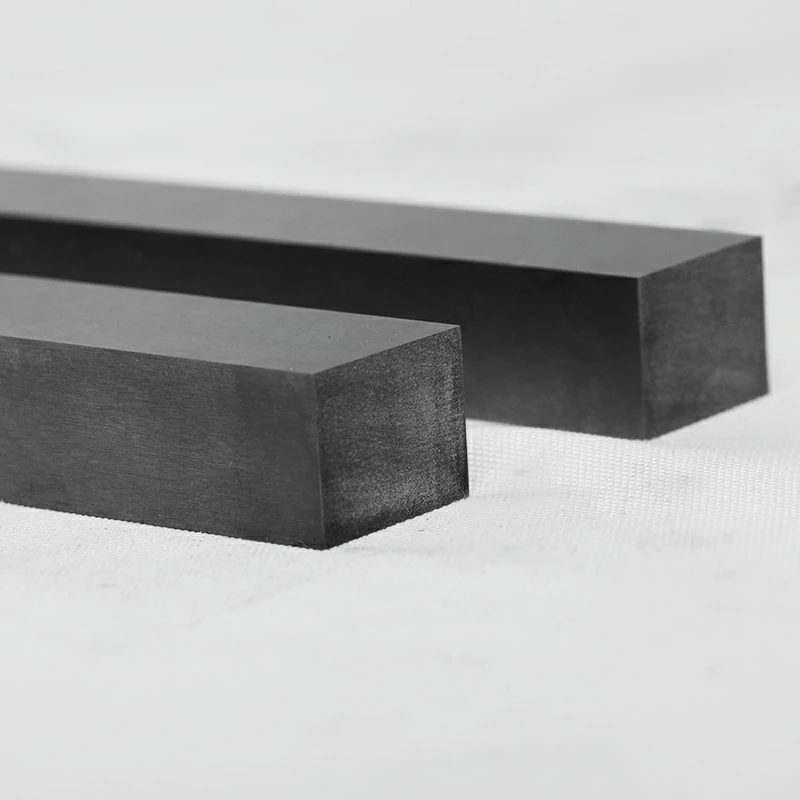

Products Description

| Classification by material | Classification by surface condition |

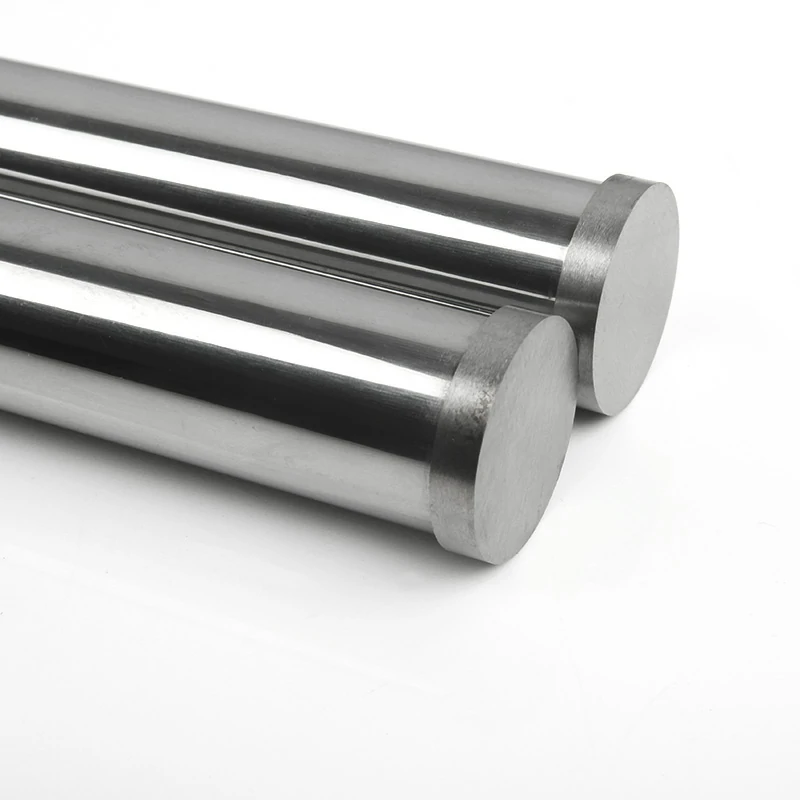

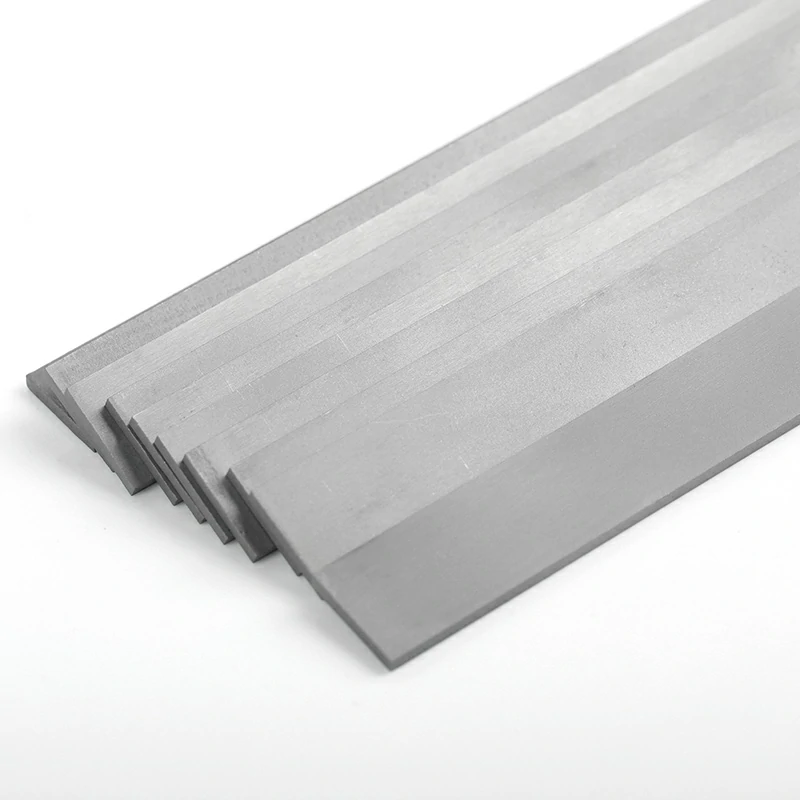

| ①Pure molybdenum rods: molybdenum content greater than 99.95%. | ①Sintered molybdenum rods: silver grey metallic lustre on the surface. |

| ②High temperature molybdenum rods (molybdenum-lanthanum alloy rods): containing 0.4~1.2% lanthanum, molybdenum content is the residual amount except impurities. | ②Wrought molybdenum rods: with a layer of oxide on the surface and a black surface. |

| ③Turned molybdenum rods: metallic lustre on the surface, flat and rough. |

| ③TZM molybdenum rods: 0.4~0.6Ti, 0.07~0.12Zr, 0.01~0.05C. | ④Brushed molybdenum rods: silvery grey metallic lustre with a smooth surface and small dimensional errors. |

Introduction, Process and Applications

Molybdenum rods have a high melting point, good thermal conductivity and low thermal expansion properties. At high temperatures, they can resist oxidation and have high strength. Molybdenum rods can be used in the manufacture of electric vacuum devices and electric light source components, as well as high temperature heat emitters and high temperature structural components, electrodes, etc.

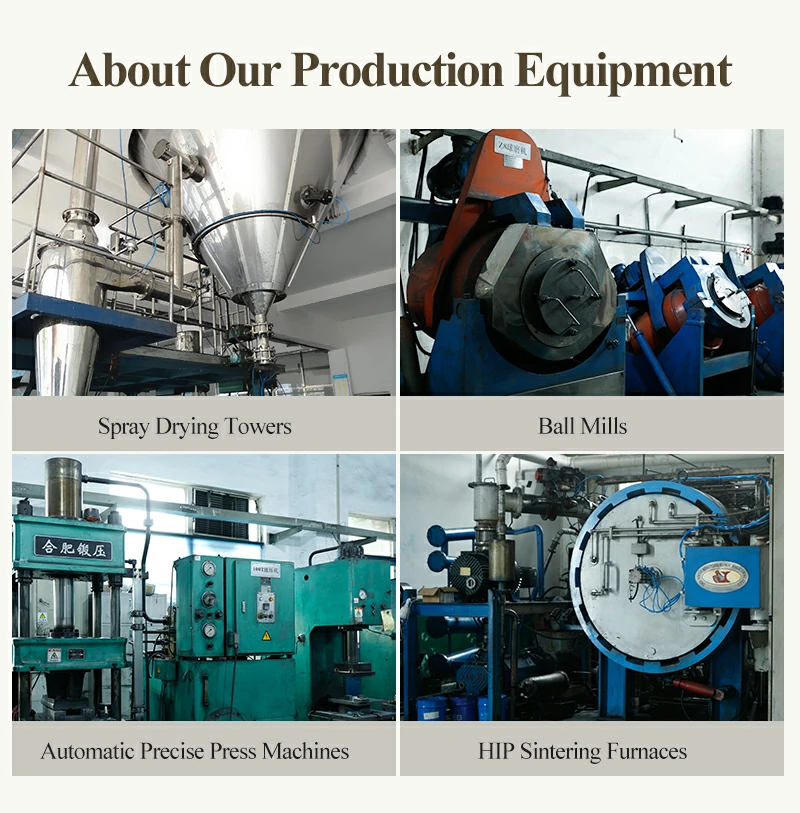

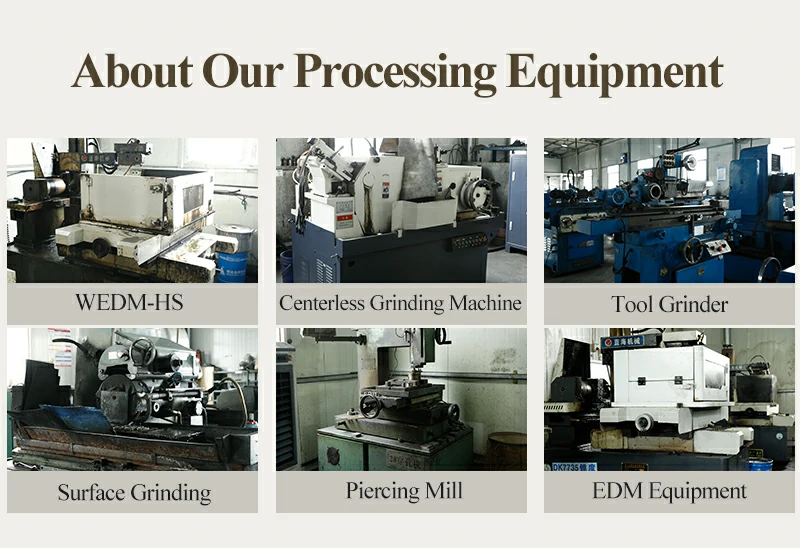

The typical production process involves forming, sintering, pendant forging, and machining.

Applications include:

① For the manufacture of electric vacuum devices and electric light source parts.

② Suitable for processing ion implantation type parts.

③ Used as high temperature heat generators and high temperature structural parts.

④ Used as an electrode for furnaces in the glass and refractory fibre industries, working in molten glass at 1300°C with a long life.

⑤ Used as an electrode in the rare earth industry.

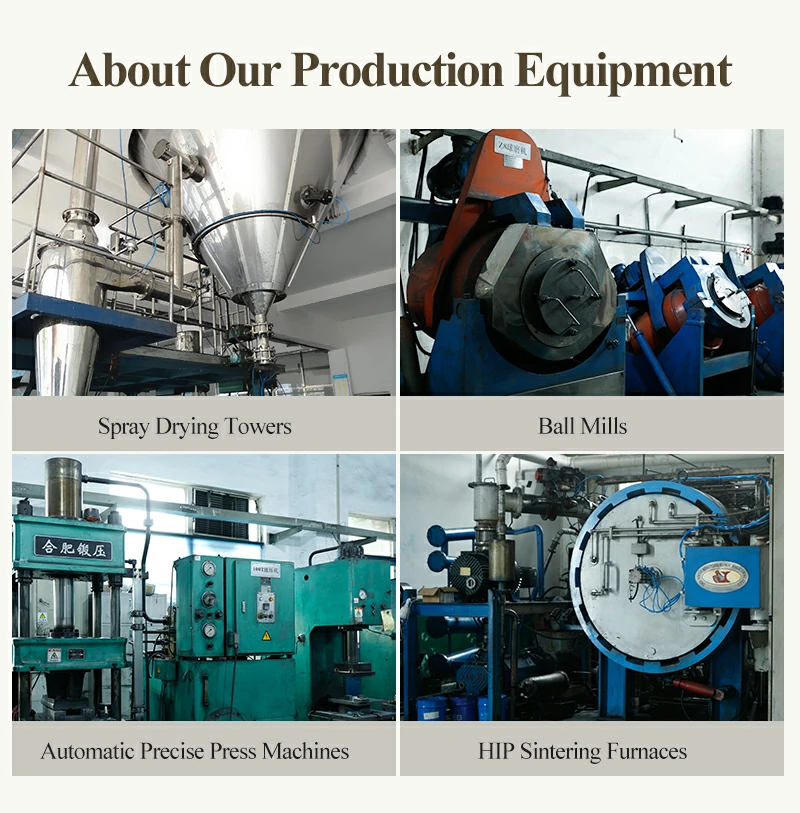

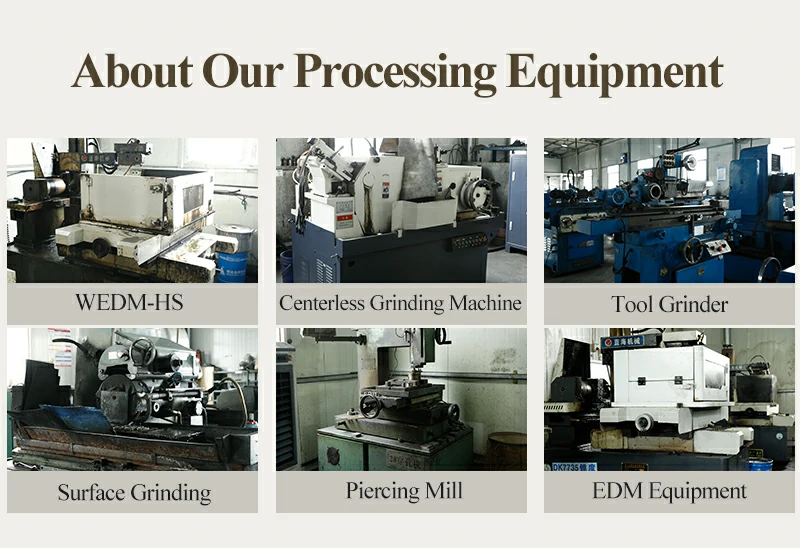

Company Profile