How an Iranian Industrial Group Reinvented Roller Press Performance with HAO CARBIDE

Writer: admin Time:2025-12-24 15:27:46

An industrial group in Iran faced constant disruption from its raw material roller press. Scheduled hardfacing maintenance every 4–5 months caused unpredictable downtime, high repair costs, and inefficient energy use, creating a significant bottleneck in production.

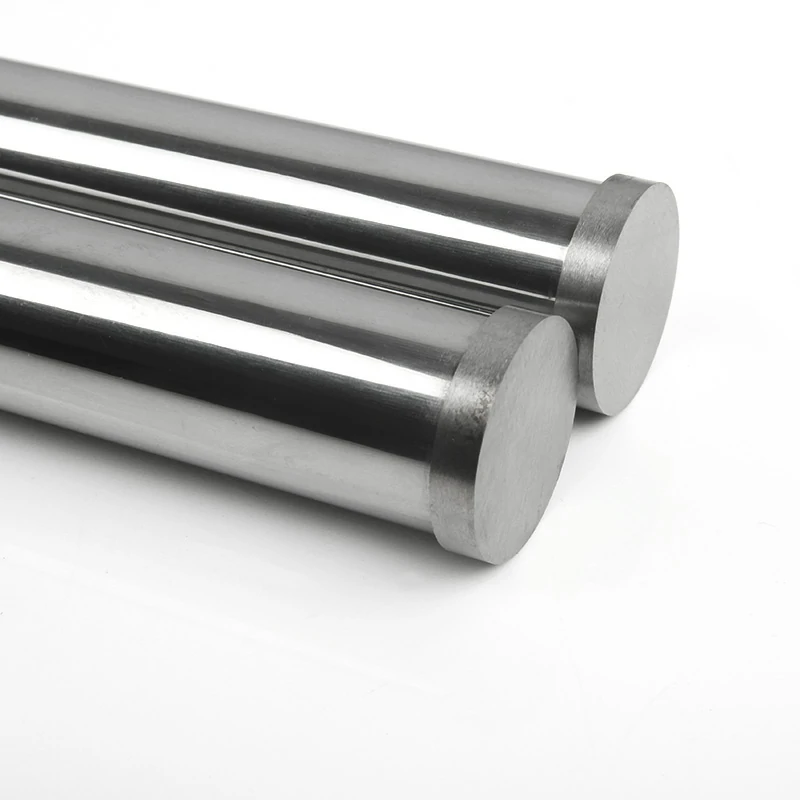

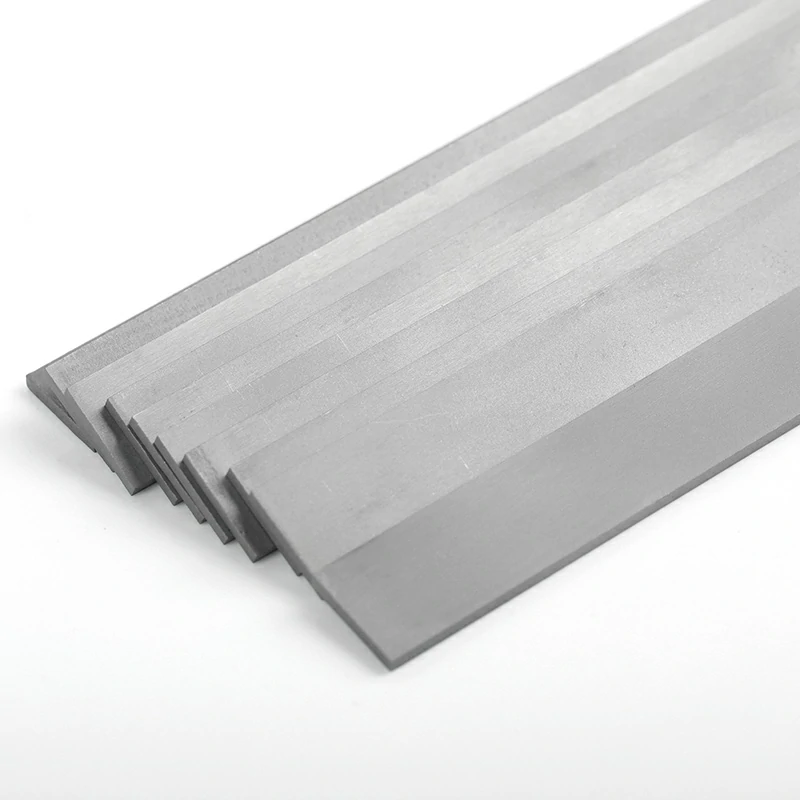

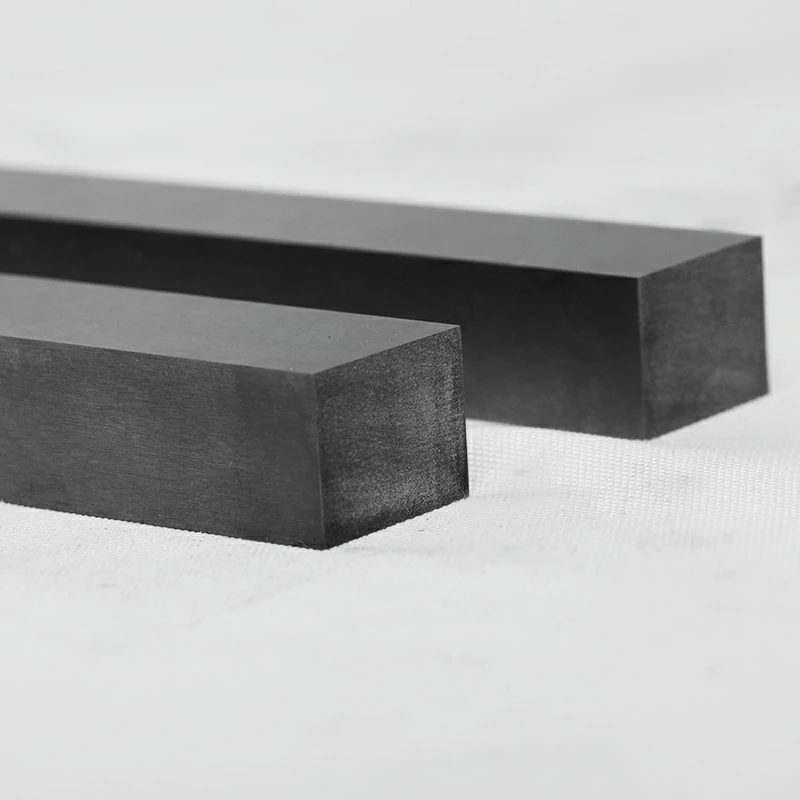

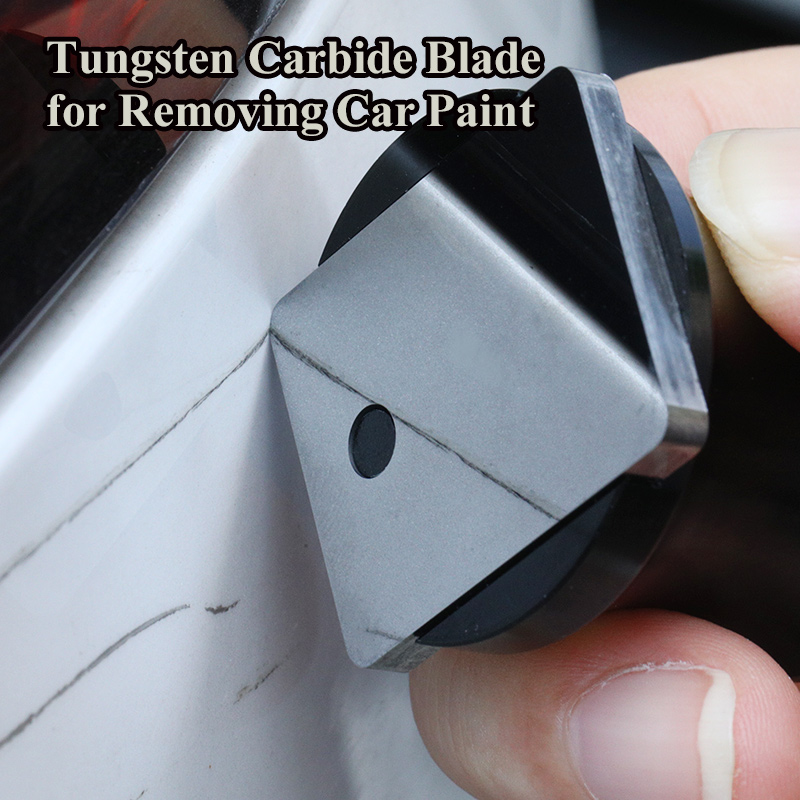

To break this cycle, the group partnered with HAO CARBIDE for a fundamental upgrade: replacing the traditional welded surface with engineered Tungsten Carbide Studs for HPGR Rollers. This solution shifted the maintenance strategy from reactive, frequent repairs to proactive, long-term protection, leveraging a material specifically designed to withstand extreme abrasive wear and high-pressure impact. The result is a durable Studded roller surface that maintains profile stability over extended periods.

The transformation delivered clear, multi-faceted results:

Extended Uptime: Continuous operation was achieved for 18 months without major maintenance.

Increased Productivity: Approximately 400 hours of lost production time were recovered annually.

Substantial Savings: Direct reductions in maintenance and energy costs generated annual savings exceeding RMB 1 million, with a full return on investment in under a year.

Reliable Performance Across Applications

HAO CARBIDE tungsten carbide studs deliver outstanding wear resistance and high compressive strength, ensuring stable operation under highly abrasive conditions. In applications such as a carbide stud for roller sleeve, their proven service life across typical materials is summarized below:

| Material Type | Service Life (Operating Hours) |

|---|

| Iron Ore | 8,000 – 10,000+ |

| Cement Raw Meal | 25,000+ |

| Clinker | 30,000+ |

These studs enhance grinding efficiency, reduce maintenance frequency, and support continuous, cost-effective production in demanding mineral and cement processing environments.

In the client's words:

"Partnering with HAO CARBIDE was a strategic decision that addressed our core challenge of unplanned downtime. The extended service life and significant financial savings confirm the high return on this investment. Their expertise made them a trusted partner in achieving these results."